The Impact of Inflation on Chip Production and Availability

The global economy has recently witnessed a resurgence of inflationary pressures, causing ripple effects across various industries. One sector that these price surges have significantly impacted is the semiconductor industry. The intricate dance between inflation and chip production has created a challenging landscape, leading to supply shortages and increased costs. In this article, we delve into how inflation affects chip production and availability and how some companies, like Spectrum, are navigating these turbulent waters.

The Inflationary Ripple Effect

Inflation, characterized by a sustained increase in the general price level of goods and services, has repercussions far beyond the consumer market. One of the most striking effects of inflation is its direct impact on production costs. As raw materials, labour, and transportation prices rise, manufacturers face tough decisions: either absorb the increased expenses or pass them on to consumers through higher prices. Even slight cost fluctuations can lead to significant disruptions in the semiconductor industry, which relies on intricate supply chains and delicate manufacturing processes.

The Semiconductor Shortfall

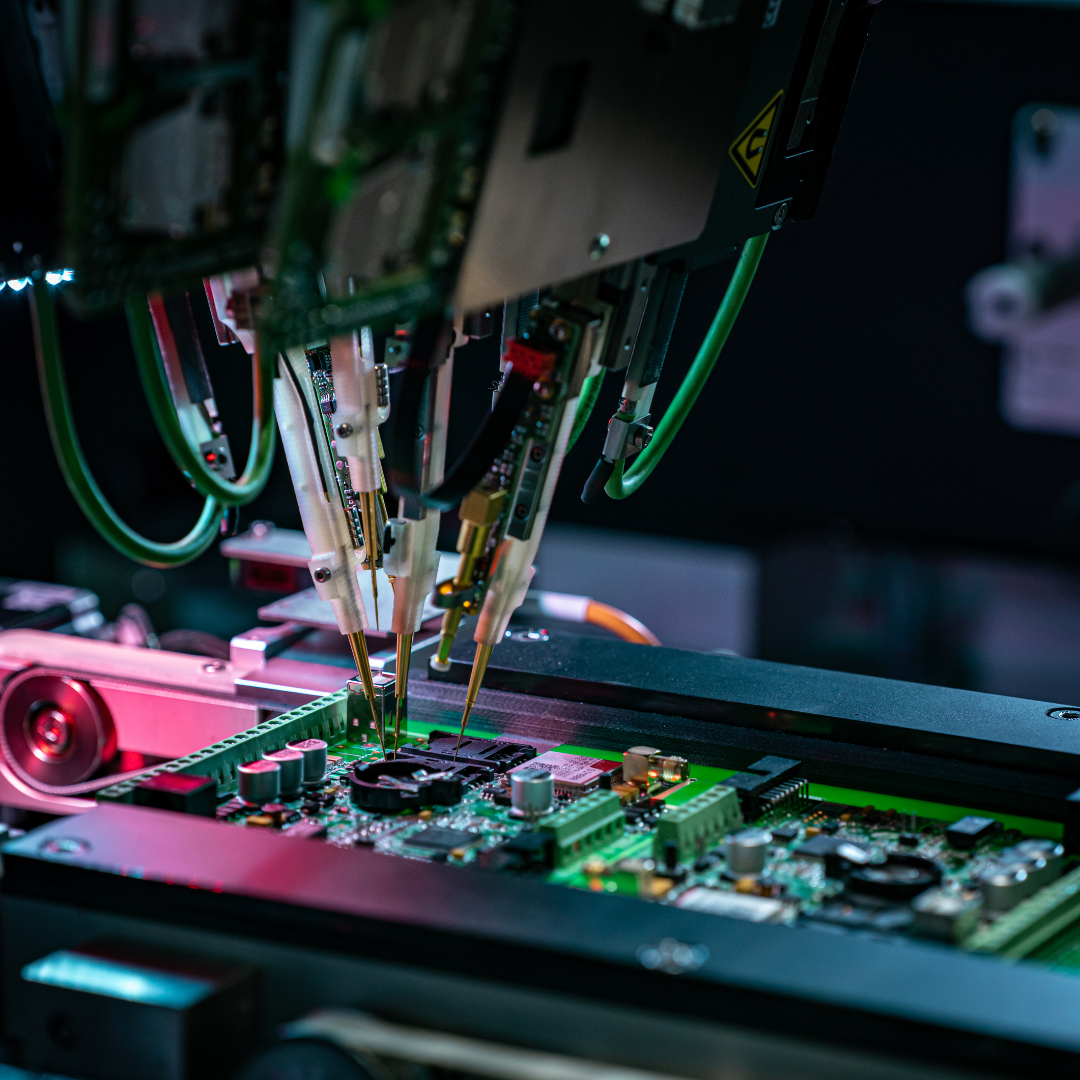

The semiconductor industry, already grappling with supply chain disruptions due to the pandemic, is particularly vulnerable to inflation. The production of chips requires an intricate ecosystem of specialized equipment, rare materials, and highly skilled labour. Any disturbances in this delicate balance can result in reduced output. With inflation driving up the costs of these essential components, semiconductor manufacturers find themselves caught in a difficult bind. The challenge becomes twofold: managing increased expenses while meeting the soaring demand for chips, driven by the rapid expansion of digital technologies and the Internet of Things (IoT).

Navigating the Turbulence – Spectrum’s Approach

Amid these inflation-induced challenges, companies like Spectrum have proactively safeguarded chip production and availability. By implementing a multifaceted approach, they aim to mitigate the impact of inflation on their operations and, in turn, on their customers:

1. Diversified Sourcing: Spectrum has adopted a diversified sourcing strategy, collaborating with suppliers from various regions. This approach helps them reduce the risk of supply chain disruptions caused by inflation-driven upheavals in any area.

2. Efficiency Enhancements: Spectrum has focused on optimizing its manufacturing processes to enhance operational efficiency. This includes streamlining workflows, minimizing waste, and adopting energy-efficient practices. These efforts help offset the increased costs associated with inflation.

3. Proactive Planning: Spectrum has employed predictive analytics to anticipate inflation-driven disruptions and fluctuations in demand. This enables them to make informed decisions in advance, ensuring their stocks remain well-stocked and ready to meet market demands.

4. Competitive Pricing: Despite the challenges posed by inflation, Spectrum remains committed to offering competitive prices to its customers. By implementing efficient cost management strategies, they can maintain pricing that resonates well in the market.

Inflation’s impact on chip production and availability is a complex challenge that requires innovative solutions and strategic planning. Companies like Spectrum Components set an example by proactively managing their operations to ensure a steady supply of chips and competitive prices as the semiconductor industry adapts to these changing economic conditions. In a world where uncertainty prevails, their approach offers hope for maintaining stability in an ever-evolving industry. So, while the waves of inflation continue to crash upon the shores of various sectors, Spectrum stands firm, prepared to weather the storm and emerge stronger than before.